A gas analyzer is a device used in Continuous Emission Monitoring Systems(CEMS) for analysis of stack emissions for its regulation and control.

In this article, you’ll know how a flue/stack gas analyser works.

There are different types of gas analysers available out there. And each type has a different working principle. This also ensures that different types of gas emissions can be monitored analysed.

This article will focus itself on IR type of Gas Analysers out of various other types.

Why continuous stack monitoring is important?

But before, talking about the need for continuous stack emission monitoring and so the system, the emissions coming out of the industrial stacks contains gases like CO2, CO, NOx, SOx, CH4, etc. These gases are some of the major pollutants responsible for global warming. If left unmonitored and uncontrolled and for a long period of time, they might turn to be lethal to the surrounding population and other living organisms sustaining around the industrial area.

What are the different types of Gas Analysers?

The different types of Gas Analysers available are-

- Gas Chromatography Analysers

- IR based Gas Analysers

- Thermal Conductivity Gas Analysers

- Paramagnetic Gas Analysers

- Electrochemical Analysers

- ORSAT Analysers

- Gravimetry type Analysers

- Methanometer Analysers

How do IR Gas Analyzers work?

IR stands for infrared, which is electromagnetic radiation having a wavelength greater than the visible white light. IR Gas Analysers imply those devices that make use of infrared(IR) beams for their functioning.

The basic principle behind the working of an IR type of analyzer is that, the amount of IR beam will get absorbed by stack gas placed under the test and that will be proportional to the concentration of gases present in it.

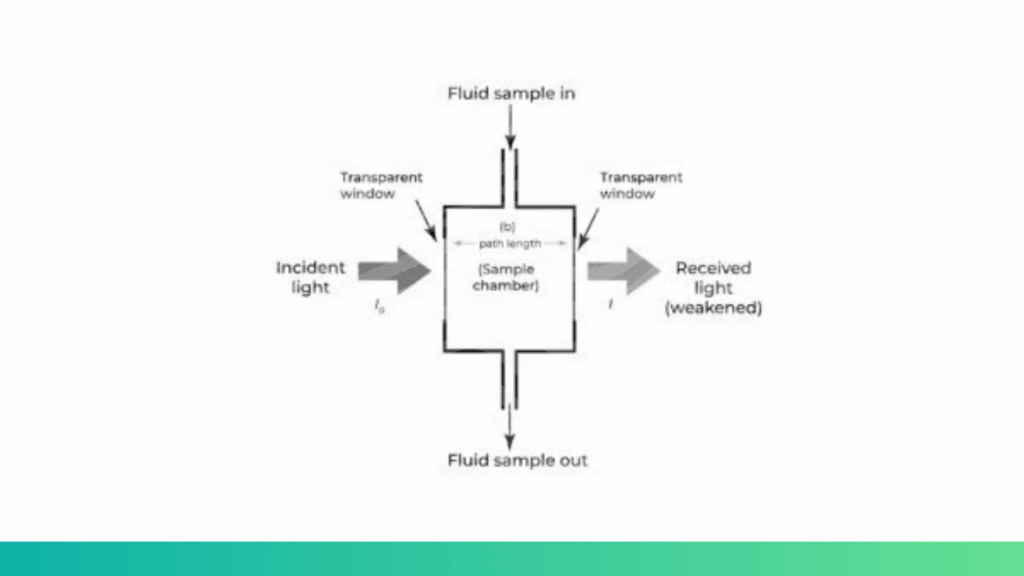

The process of gas absorption is governed by the Beer-Lambert Law, which is the fundamental equation relating any photon absorption process to a substance’s concentration.

A=abc=log(I/Io)

where,

A – Absorbance

a – Extinction co-efficient for photon absorbing substance

b – Path length of the light that travels through the substance

c – Concentration of the photon absorbing substance placed under the test

Io – Intensity of the source light projected into the sample

I – Intensity of the light received after coming out of the sample

The IR Gas Analysers are further classified into 2 types-

Types of IR Analysers

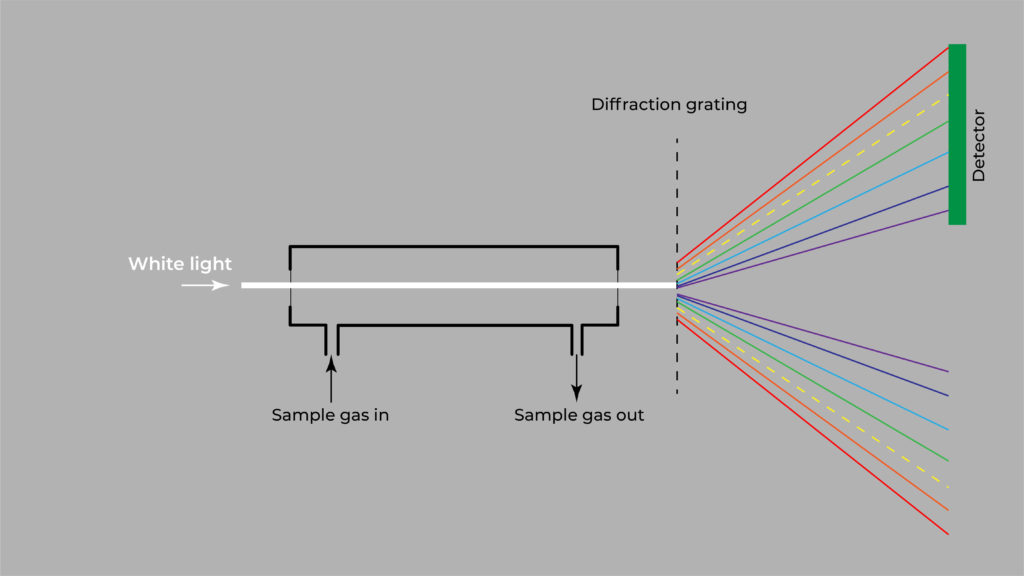

1. Dispersive type of IR Analysers

In the dispersive type of IR Analyzers, white light is passed through the continuously flowing emission gas kept under the test. The light coming out of the transparent side of the chamber is then made to fall on a diffraction grating to disperse it into a spectrum. The individual wavelengths of light dispersed are then analyzed to get emission insights. This works as the test gas absorbs certain wavelengths of light corresponding to its concentration.

2. Non-Dispersive type of IR Analysers(NDIR)

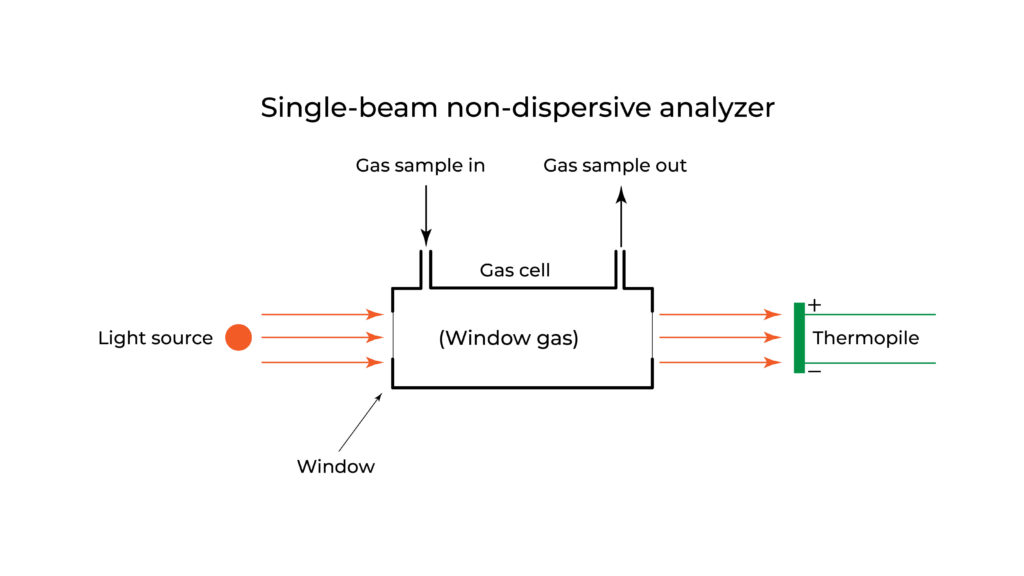

The non-dispersive analyzers are again are of two types based upon the source of light that is emitted to the testing sample.

Single Beam type Analyser

In a single beam type analyzer, a single source/beam of light is allowed to pass through the chamber of sample gas(also called a cell) under the test. The sample gas is also allowed to flow continuously through the chamber. The light coming out of the other transparent side of the chamber is captured using a thermo-pile, that converts the light energy into heat and finally into voltage for emission analysis.

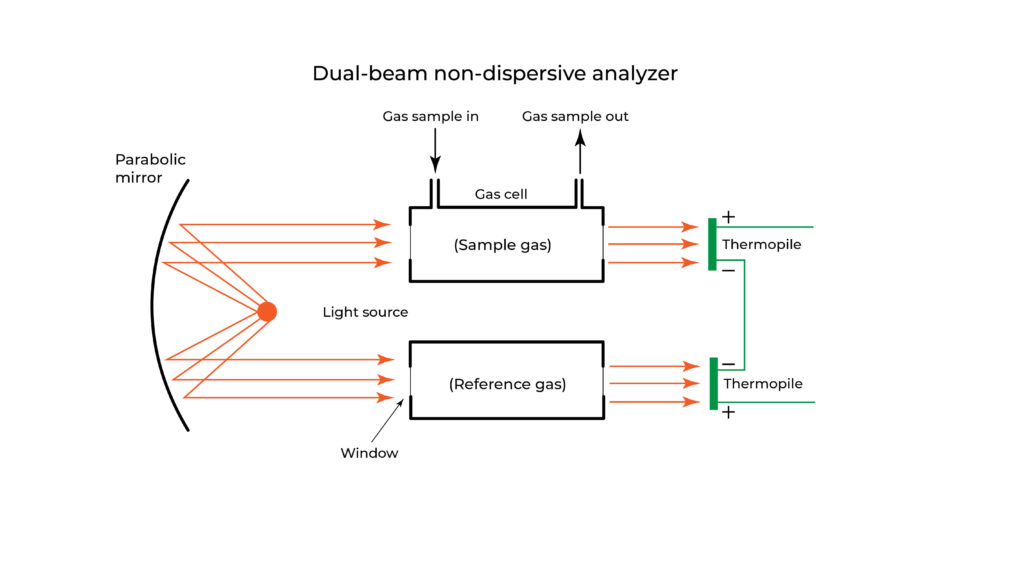

Dual Beam type Analyser

In dual-beam type, the source of light is split using parabolic mirrors, creating two sources of beams to fall on the gas sample.

The gas chambers are also divided and 2 different chambers are placed for each source of light, one chamber with a reference gas completely sealed inside it, and another with a continuous flow of gas to be analysed. The light arriving out of these chambers are now collected using 2 different thermo-piles. The thermo-piles outside are connected in series but in opposite fashion to cancel out the equal voltages. The voltage difference between the thermo-piles obtained is used for creating numerical and graphical representations to perform emission analysis.